High Bay LED Lights Manufacturer

We offers a wide variety of High Bay Light to meet your every need.

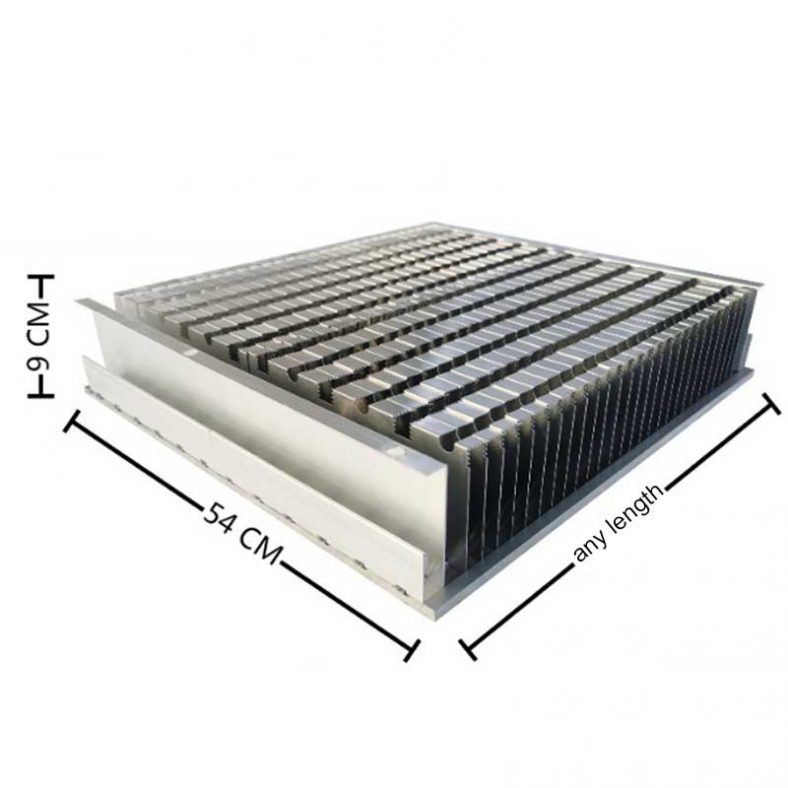

Wandan offers safe and durable led high bay light in bulk. Our led high bay light have different exterior designs and thermal research that are suitable for every indoor occasion. Good cooling heatsink help maintain the quality and life of the led high bay led lights. We offer ufo led high bay light and shoe box light, yet some prefer to have traditional round high bay lights. Beside, we also offer Linear high bay LED lights, Tri-proof high bay LED lights, Vapor-tight high bay LED lights, and Retrofit high bay LED lights. More so, if the things you need are not available, feel free to get in touch with us. We offer full assistance in customizing led high bay light, from Install to parts match.

High Bay LED Lights

Wandan Lighting specialist offers a wide variety of High Bay Light to meet your every need.

High bay LED lights are lighting fixtures designed for use in spaces with high ceilings, typically 20 feet or higher. These lights are often used in industrial and commercial settings such as warehouses, gymnasiums, manufacturing facilities, and large retail stores.

High bay LED lights are designed to provide bright, efficient lighting that covers a large area. They are typically mounted on the ceiling or suspended from cables, and can be angled to direct light where it is needed most. LED technology is preferred over traditional lighting sources such as fluorescent or high-intensity discharge (HID) lamps because of its energy efficiency, longer lifespan, and lower maintenance costs.

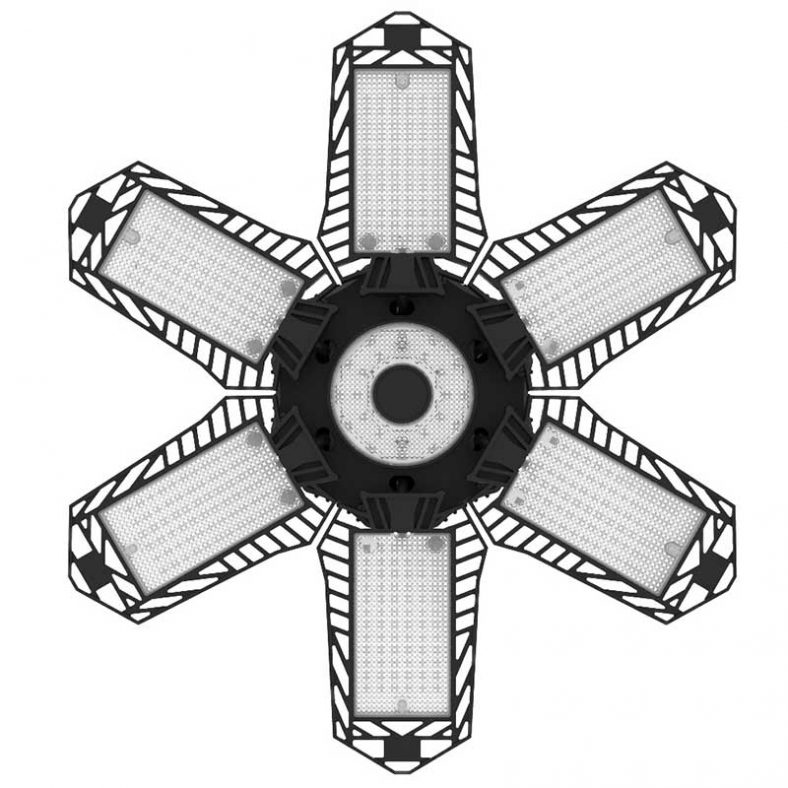

High bay LED lights come in a variety of shapes and sizes, including round, rectangular, and linear designs. They can also be equipped with various features such as dimming controls, motion sensors, and color temperature adjustments to provide maximum flexibility and energy savings.

Relate High Bay LED Lights

Wandan Lighting specialist offers a wide variety of High Bay Light to meet your every need.

-

100W150W200W240W High quality Die casting aluminum led highbay light

-

High Power Professional Employment 200W 500W Industry Led Highbay Light

-

Newest Ufo Led High Bay Light

-

6-Leaf High Power LED High Bay Light For Garage

-

60w-480w E27/E40 Disk Fin LED Corn Lights

-

100 150 200W Wide Angle UFO LED High Bay Lights

-

Durable Honeycomb Fin High Bay Lights

-

E27 & E40 High-Power Aluminum LED Corn Lights For Landscape Used

-

E27 Screw Household 200W Bulb Light

-

300W High-Power Bright Fin High Bay Lamp

-

100w-200w Slim Fin Series LED High Bay Light

-

High Power LED Bulb Light With High Lumen LEDs

-

Ultra-Thin LED Industrial And Mining Lamp

-

LED Anti-Glare UFO LED High Bay Light【Private Products】

-

High Power Ultra-Bright LED High Bay Light For Factory

-

3D Heat Dissipation Ufo LED High Bay Light

-

Wholesale LED Tower Chandelier With Mingwei Power Supply

-

Heat Pipe LED High Bay Light With Osram 3030 Chips

-

High Thermal Conductivity High Bay Light With Fish Scale Reflector

-

30000lm 100W To 250W UFO Led High Bay Light

LED High bay light Projects / Solutions / Applications

Mainly applicable to warehouses, supermarkets, large workshops, steel factories, shipyards, aircraft manufacturers, large machinery factories, hardware workshops, warehouses, highway toll stations, gas stations, large supermarkets, exhibition halls, gymnasiums, car waiting halls, trains Station waiting hall and other places that require high space lighting.

LED High bay light Kits/Parts

Wandan Lighting specialist offers a wide variety of High Bay Light to meet your every need.

LED High bay light Buy guide

Wandan Lighting specialist offers a wide variety of High Bay Light to meet your every need.

An LED high bay is a type of lighting fixture designed to provide high-intensity lighting in large indoor spaces with high ceilings, such as warehouses, factories, and gymnasiums. These fixtures typically use LED (light-emitting diode) technology to provide bright, efficient lighting while consuming less energy than traditional high-intensity discharge (HID) lights, such as metal halide and high-pressure sodium lamps.

LED high bays are often suspended from the ceiling with chains or hooks, and may include reflectors or lenses to direct the light output downwards towards the work or activity area. They are often designed with a rugged, durable construction to withstand harsh industrial environments, and may also feature advanced controls or sensors to further optimize their performance and energy efficiency.

As of my knowledge cutoff date of September 2021, the global high bay lighting market size was valued at USD 8.4 billion in 2020 and was expected to reach USD 13.4 billion by 2025, with a compound annual growth rate (CAGR) of 9.7% during the forecast period (2020-2025).

The high bay lighting market refers to the market for lighting solutions used in high-ceilinged spaces such as warehouses, factories, gymnasiums, and other industrial and commercial settings. The growth of this market is driven by several factors, including the increasing adoption of energy-efficient lighting technologies, rising demand for intelligent lighting systems, and growing awareness of the benefits of LED lighting.

Factors such as the growing trend towards smart cities, advancements in wireless communication technologies, and the increasing adoption of the Internet of Things (IoT) are also expected to drive the growth of the high bay lighting market in the coming years. Additionally, the rising focus on sustainability and energy efficiency is expected to create significant opportunities for the growth of the market.

It is worth noting that market conditions are subject to change over time, and the current state of the high bay lighting market may differ from the information provided here due to various economic, social, and technological factors.

Choosing the right high bay lights requires considering several factors to ensure that you select a lighting solution that meets your specific needs. Here are some factors to consider when choosing high bay lights:

- Ceiling Height: The height of the ceiling in the space where the high bay lights will be installed is a critical factor in determining the type of lights to choose. A higher ceiling requires lights with higher lumen output and narrower beam angles to ensure adequate lighting levels at the floor.

- Lighting Requirements: Consider the type of work or activity that will be taking place in the space where the high bay lights will be installed. High bay lights should provide adequate illumination for the activity or task, and this should be reflected in the lighting requirements.

- Energy Efficiency: LED high bay lights are typically more energy-efficient than traditional lighting options. Consider the energy efficiency of the high bay lights to reduce energy consumption and lower operating costs.

- Color Temperature: Color temperature refers to the perceived warmth or coolness of the light emitted by a light source. Choose the color temperature that best suits your lighting requirements.

- Durability: High bay lights are typically used in industrial settings, and they should be durable enough to withstand harsh environments. Choose lights with a high IP rating and robust construction to ensure longevity and reduce maintenance costs.

- Lighting Controls: Consider the availability of lighting controls to manage and control the lighting output. Dimming controls, motion sensors, and timers can help to reduce energy consumption and improve lighting efficiency.

- Budget: Consider the initial cost of the high bay lights and their long-term operating costs. Choose lights that provide the best value for money and align with your budget.

By considering these factors, you can select high bay lights that are optimal for your specific needs, ensuring that your workspace is adequately illuminated for optimal productivity and safety.

LED (Light Emitting Diode) high bay lights offer several advantages over traditional lighting options, including:

- Energy Efficiency: LED high bay lights are highly energy-efficient and use up to 80% less energy than traditional lighting options. This translates to lower energy bills and reduced environmental impact.

- Longevity: LED high bay lights have a much longer lifespan than traditional lighting options, with an average lifespan of around 50,000 hours. This means that they require less maintenance and replacement, reducing operating costs.

- Improved Lighting Quality: LED high bay lights provide better quality lighting than traditional lighting options, with more accurate color rendering, higher color temperature options, and brighter illumination levels.

- Instant On/Off: LED high bay lights turn on and off instantly, eliminating the warm-up time required by traditional lighting options. This means that they can be used for motion sensor applications or areas where lights are frequently turned on and off.

- Design Flexibility: LED high bay lights offer greater design flexibility, with a variety of mounting options, beam angles, and color temperature options available. They can be tailored to specific lighting requirements, making them suitable for a wide range of applications.

- Environmental Friendliness: LED high bay lights do not contain hazardous materials such as mercury, making them safer for the environment. Additionally, they emit less heat, reducing the need for air conditioning and further reducing energy consumption.

- Cost-Effectiveness: While LED high bay lights may have a higher initial cost than traditional lighting options, they provide a faster return on investment due to their energy efficiency and longevity, resulting in lower operating costs over time.

In summary, LED high bay lights offer a range of advantages over traditional lighting options, including energy efficiency, improved lighting quality, longevity, design flexibility, environmental friendliness, and cost-effectiveness.

LED (Light Emitting Diode) high bay lights work by converting electrical energy into light through a semiconductor material. Here’s a brief overview of how they work:

- Electrical Current: When electrical current passes through the semiconductor material in the LED chip, it excites the electrons in the material, causing them to release energy in the form of photons (light particles).

- Semiconductor Material: The semiconductor material used in LED high bay lights is typically made of a combination of different materials, including gallium, arsenic, and phosphorus. The specific combination of materials determines the color of the light emitted by the LED.

- Heat Dissipation: LED high bay lights generate less heat than traditional lighting options, but they still require proper heat dissipation to maintain optimal performance. Heat sinks and other cooling methods are typically used to keep the LED chip cool.

- Driver: An LED driver is required to convert the incoming AC power supply to the DC power required by the LED chip. The driver also regulates the current and voltage supplied to the LED chip, ensuring that it operates within its optimal range.

- Reflector and Lens: A reflector or lens is typically used to direct and focus the light emitted by the LED high bay light. This helps to increase the efficiency of the lighting and ensure that it is directed where it is needed.

Overall, LED high bay lights use semiconductor technology to convert electrical energy into light, providing an energy-efficient and long-lasting lighting solution for a range of industrial and commercial applications.

The price of LED (Light Emitting Diode) high bay lights can vary depending on several factors. Here are some factors that can affect the price of LED high bay lights:

- Quality: The quality of the LED chip, driver, and other components used in the high bay light can affect the price. High-quality components typically cost more, but they provide better performance, longevity, and reliability.

- Brand: The brand of the LED high bay light can also affect the price. Well-known and established brands may cost more due to their reputation for quality and reliability.

- Wattage and Lumen Output: The wattage and lumen output of the LED high bay light can affect the price. Higher wattage and lumen output typically cost more due to the increased power and performance.

- Color Temperature and CRI: The color temperature and CRI (Color Rendering Index) of the LED high bay light can affect the price. Higher color temperature and CRI typically cost more due to the increased quality of light.

- Design and Features: LED high bay lights can come in different designs and with various features such as dimming capabilities, motion sensors, and smart controls. These additional features can affect the price.

- Quantity: The quantity of LED high bay lights purchased can affect the price. Bulk purchases may result in a lower price per unit.

- Certification and Compliance: LED high bay lights that meet specific certification and compliance standards may cost more due to the additional testing and requirements.

In summary, the price of LED high bay lights can be affected by several factors, including quality, brand, wattage and lumen output, color temperature and CRI, design and features, quantity, and certification and compliance. It is essential to consider these factors when choosing LED high bay lights to ensure that you select the best option that fits your needs and budget.

If your high bay lights are flickering, there are several steps you can take to troubleshoot and resolve the issue:

- Check the Power Supply: Ensure that the power supply to the high bay lights is stable and consistent. If the voltage fluctuates, it can cause the lights to flicker. You can use a multimeter to test the voltage at the power supply and the input to the driver.

- Inspect the Wiring: Check the wiring connections between the high bay lights and the power supply or driver. Loose or damaged wiring can cause flickering. Ensure that all connections are secure and there are no damaged wires.

- Check the Driver: The driver of the high bay lights regulates the voltage and current supplied to the LED chips. If the driver is damaged or faulty, it can cause flickering. Check the driver for any signs of damage, and replace it if necessary.

- Clean the Fixtures: Dirt or debris can accumulate on the surface of the high bay light fixtures and cause flickering. Clean the fixtures with a soft cloth or a blower to remove any dust or debris.

- Replace the LED Chips: If none of the above steps resolve the issue, the LED chips may be faulty or damaged. You can replace the LED chips or consider replacing the entire fixture if necessary.

It is recommended to contact a qualified electrician or lighting technician to diagnose and fix any issues with your high bay lights. Flickering lights can indicate a potentially hazardous electrical issue, so it is essential to address the issue promptly to ensure safety and prevent damage to the lighting system.

The installation spacing for LED (Light Emitting Diode) high bay lights depends on several factors, including the height of the ceiling, the size of the space, and the required lighting level. Here are some general guidelines to consider when determining the installation spacing for LED high bay lights:

- Ceiling Height: The higher the ceiling, the more space between the fixtures is needed. For example, if the ceiling height is 20 feet, the recommended spacing between fixtures is typically around 30-40 feet.

- Light Output: The light output of the LED high bay light should also be considered when determining the installation spacing. The higher the light output, the more space between fixtures is typically required.

- Coverage Area: The size of the space and the required lighting level should also be considered when determining the installation spacing. For example, a warehouse may require a higher lighting level than a gymnasium, which would require more fixtures and a smaller installation spacing.

- Uniformity: It is important to ensure that the light distribution is uniform throughout the space. The installation spacing should be determined in a way that avoids hot spots and dark spots.

- Safety: It is important to ensure that the installation spacing complies with local building and safety codes, including the requirements for emergency lighting and egress lighting.

It is recommended to consult with a qualified lighting professional or electrical engineer to determine the appropriate installation spacing for your specific application. They can provide recommendations based on your space, lighting needs, and local regulations to ensure safe and efficient lighting.Wandan Lighting Recommended installation height:

- Recommended installation height of 30W LED high bay light: 3m Installation spacing: 10-15m

- Recommended installation height of 40W LED high bay light: 4m Installation spacing: 15-20m

- Recommended installation height of 45W LED high bay light: 5m Installation spacing: 15-18m

- Recommended installation height of 50W LED high bay light: 6m Installation spacing: 18-22m

- LED High Bay Light 55W Recommended installation height: 7m Installation spacing: 20-23m

- Recommended installation height of 60W LED high bay light: 8m Installation spacing: 23-25m

- Recommended installation height of >60W LED high bay light: 8m Installation spacing: >25m

Here are some common product features of high bay lights:

- The LED plane integrated light source is used, with small thermal resistance and low temperature rise. The lamp housing is a part of the radiator and conducts heat directly.

- LED industrial and mining lights use a wide voltage design. When the voltage fluctuates, the total power of the lamp body basically does not change, avoiding stroboscopic flicker, and ensuring the stability of the lighting environment for workers.

- No dust, no mosquitoes, save the trouble of cleaning the light source lamp body frequently.

- Compared with traditional halogen lamps and high-pressure sodium lamps, it adopts LED plane integrated light source, non-polluting materials and ultraviolet and infrared radiation to create a healthy and comfortable working environment.

- Make full use of the advantages of LED instant start, start the lamps instantly in places where LED industrial and mining lights are used in large areas, and improve work efficiency.

- LED Technology: High bay lights use LED (Light Emitting Diode) technology to provide high-quality, energy-efficient lighting.

- High Lumen Output: High bay lights typically have a high lumen output, which provides bright and even lighting in large areas such as warehouses, factories, and gymnasiums.

- Wide Beam Angle: High bay lights usually have a wide beam angle to cover a broad area with a single fixture, reducing the number of fixtures required and increasing energy efficiency.

- Adjustable Mounting Options: High bay lights often come with adjustable mounting options, including chain, cable, and pendant mounts, allowing for easy installation and flexibility in positioning.

- Durable Construction: High bay lights are typically constructed with durable materials such as aluminum or steel to withstand harsh environments and ensure long-lasting performance.

- Optional Dimming Capabilities: Many high bay lights come with optional dimming capabilities, allowing for even greater energy savings and customization of lighting levels for different applications.

- Smart Control Options: Some high bay lights offer smart control options, including occupancy sensors, daylight sensors, and wireless controls, providing even greater energy efficiency and control over lighting levels.

- Certification and Compliance: High bay lights may come with certifications and compliance with standards such as UL (Underwriters Laboratories), DLC (DesignLights Consortium), and Energy Star, ensuring quality and performance and potentially providing access to rebates and incentives.

These are some of the common features of high bay lights. It is important to consider these features when selecting high bay lights to ensure that you choose the best option that fits your needs and budget.

LED high bay lighting and metal halide lighting are two popular types of lighting solutions for industrial and commercial applications. Here are some of the key differences between the two:

- Energy efficiency: LED high bay lights are much more energy-efficient than metal halide lights. LED lights can typically achieve energy savings of up to 70% compared to metal halide lights.

- Lifespan: LED high bay lights have a much longer lifespan than metal halide lights, typically lasting up to 100,000 hours compared to 10,000-20,000 hours for metal halide lights.

- Maintenance: LED high bay lights require much less maintenance than metal halide lights, as they don’t need to be replaced as frequently and don’t require the same level of ongoing maintenance.

- Color temperature: LED high bay lights offer a wider range of color temperatures compared to metal halide lights, allowing for more customization and better lighting quality.

- Instant on/off: LED high bay lights can be turned on and off instantly, whereas metal halide lights require a warm-up period before they reach full brightness.

- Heat emission: LED high bay lights emit much less heat than metal halide lights, making them more comfortable for workers and reducing the need for cooling systems.

Overall, LED high bay lights offer many advantages over metal halide lights, including higher energy efficiency, longer lifespan, lower maintenance requirements, and better lighting quality. While the initial cost of LED high bay lights may be higher than metal halide lights, the long-term savings in energy and maintenance costs make them a more cost-effective and environmentally-friendly lighting solution in the long run.

When buying LED high bay lights, if you first look at the price of LED high bay lights, or put the price first, you will be wrong, because the price is the most sensitive and can influence personal thoughts. Now manufacturers from all walks of life are mixed, including intermediary traders, which leads to market chaos, chaotic prices, and uneven quality.

According to the analysis of the market based on more than ten years of experience: the situation encountered by ordinary customers; when the price is low, they dare not buy it; . The main reason for this situation is that we still don’t know what to pay attention to when buying LED high bay lights.

- First: Look at the quality of LED industrial and mining lights, that is, the configuration. First of all, what brand of LED industrial and mining lamp chips are used? Imported first-line brands have high luminous efficiency, long life, low light decay, and stability. Secondly, look at the power supply. A poor-quality power supply is basically insufficient power, that is, if you take a 100w lamp, it is actually 40-50w, which will affect the life of the lamp. Then look at the material of the lamp housing. The price of the lamp also depends on the amount and purity of the aluminum used. Imported pure aluminum is used, and the heat sink is large. Naturally, more aluminum is used. Only the material used can ensure the heat dissipation effect of the lamp. In addition, the electrical box of the lamp should be made of pure aluminum, and some cast iron does not have good heat dissipation.

- Second: Talk to the supplier about the company. Observe whether the supplier is professional through talking with the other party, so as to ensure the authenticity of each accessory used and not cut corners. Some small companies sell LED high bay lights with low configuration and low price to you. After a few months of use, the lamps are broken. When you go to them, some companies have closed down or changed their company names to continue to deceive consumers.

- Third: Talk to the supplier about the price. Ask the supplier’s price system, rather than the specific product price, so that you can clearly understand the price space, so that you can see how much space is available in the price of the product you need. Then propose the product, inform the product demand, and the quotation is the supplier’s business. With so much talk, the supplier can only make a reasonable quotation.

- Fourth: place the order in time. Don’t hesitate after the negotiation, be quick, because the supplier will respond to you quickly; if you slowly place an order to buy, the supplier will also slowly prepare the goods for you, and the production of LED industrial and mining lights is always in stock. Made to order. The supplier will definitely have a lot of customers. The supplier’s handling of the order must be arranged in order and according to the pace of things, so if you are fast, the supplier will be fast!

At the same time, you have already selected the product and supplier. If you hesitate, the potential opponent of the supplier will do everything possible to destroy your order and purchase agreement. Good time to buy, you may have to spend the entire process to find a new supplier, and generally you can’t find an equally good LED high bay light supplier that satisfies you, because when you look for a supplier again You are already in a passive position

Dimming LED (Light Emitting Diode) high bay lights can be a great way to save energy and adjust the lighting level for different applications. Here’s how to dim LED high bay lights:

- Choose a Compatible Dimmer: Not all LED high bay lights are compatible with all dimmers. Ensure that you choose a dimmer that is compatible with the LED driver and the type of LED high bay light you have.

- Check the Wiring: Ensure that the wiring connections between the LED high bay lights and the dimmer switch are correct. Follow the manufacturer’s instructions carefully and ensure that the wiring is secure and connected correctly.

- Adjust the Settings: Most LED high bay lights have dip switches or software settings that allow you to adjust the dimming level. Follow the manufacturer’s instructions to adjust the settings to the desired dimming level.

- Test the Dimming: Test the dimming to ensure that it is functioning correctly. Start by adjusting the dimmer to the lowest setting and gradually increasing it until you reach the desired level. Observe the LED high bay lights to ensure that they are dimming smoothly and evenly.

- Consider External Controls: You can also consider using external controls such as occupancy sensors or timers to adjust the dimming level automatically based on occupancy or time of day.

It is essential to ensure that the LED high bay lights are compatible with the dimmer and that the wiring and settings are correct to ensure proper and safe operation. If you are unsure about any aspect of dimming LED high bay lights, it is recommended to consult with a qualified electrician or lighting technician to ensure that the dimming is done correctly and safely.

Wiring high bay LED (Light Emitting Diode) lights with a dimmer requires careful consideration to ensure safe and proper installation. Here are the general steps to follow when wiring high bay LED lights with a dimmer:

- Turn off Power: Turn off the power at the circuit breaker to ensure that there is no electrical current flowing to the wiring.

- Choose the Right Dimmer: Select a dimmer that is compatible with the LED driver and high bay LED light you are installing. Ensure that the dimmer is rated for the same voltage as the high bay LED light and the wiring.

- Wire the Dimmer: Follow the manufacturer’s instructions to wire the dimmer switch to the power supply and the high bay LED light. Ensure that the wiring connections are secure and correctly placed.

- Adjust the Settings: High bay LED lights typically have dip switches or software settings that allow you to adjust the dimming level. Follow the manufacturer’s instructions to adjust the settings to the desired dimming level.

- Test the Dimming: Turn the power back on and test the dimming to ensure that it is functioning correctly. Gradually increase the dimming level and observe the high bay LED lights to ensure that they are dimming smoothly and evenly.

- Final Check: Double-check all wiring connections to ensure that they are secure and correctly placed. Ensure that the installation complies with local building and safety codes, including requirements for emergency lighting and egress lighting.

It is essential to ensure that the wiring is done correctly and safely when installing high bay LED lights with a dimmer. If you are unsure about any aspect of wiring high bay LED lights with a dimmer, it is recommended to consult with a qualified electrician or lighting technician to ensure that the wiring is done correctly and safely.

Sizing LED (Light Emitting Diode) high bay lighting requires careful consideration to ensure that the lighting solution provides adequate illumination for the intended space. Here are the general steps to follow when sizing LED high bay lighting:

- Determine the Space: Measure the height, length, and width of the space where the LED high bay lighting will be installed. This information will help to determine the lighting requirements for the space.

- Determine the Lighting Level: The lighting level required for the space depends on the type of activity that will be performed in the area. For example, a warehouse may require a higher lighting level than a gymnasium. The lighting level is measured in foot-candles or lux.

- Calculate the Lumens Required: The lumens required for the space can be calculated by multiplying the area of the space by the required lighting level in foot-candles or lux. This will give you the total lumens required for the space.

- Choose the LED High Bay Lighting Fixture: Choose an LED high bay lighting fixture that meets the lumens required for the space. The lumens output of LED high bay lighting fixtures is typically provided in the product specifications.

- Determine the Quantity of Fixtures: Divide the total lumens required for the space by the lumens output of the chosen LED high bay lighting fixture. This will give you the quantity of fixtures needed to adequately illuminate the space.

- Determine the Installation Spacing: The installation spacing of the LED high bay lighting fixtures should be determined based on the height of the ceiling, the size of the space, and the required lighting level.

It is recommended to consult with a qualified lighting professional or electrical engineer to ensure that the sizing of the LED high bay lighting is done correctly and safely. They can provide recommendations based on your space, lighting needs, and local regulations to ensure safe and efficient lighting.

Wiring LED (Light Emitting Diode) high bay lights is a straightforward process that requires careful attention to ensure safe and proper installation. Here are the general steps to follow when wiring LED high bay lights:

- Turn off Power: Turn off the power at the circuit breaker to ensure that there is no electrical current flowing to the wiring.

- Mount the Fixture: Mount the LED high bay light fixture according to the manufacturer’s instructions, ensuring that it is securely mounted and in the desired location.

- Wire the Fixture: Connect the wiring from the power supply to the wiring of the LED high bay light fixture according to the wiring diagram provided by the manufacturer. Ensure that the wiring connections are secure and correctly placed.

- Grounding: Connect the ground wire from the power supply to the grounding screw on the LED high bay light fixture.

- Test the Fixture: Turn the power back on and test the LED high bay light fixture to ensure that it is functioning correctly. Observe the fixture to ensure that it is providing bright and even lighting.

- Final Check: Double-check all wiring connections to ensure that they are secure and correctly placed. Ensure that the installation complies with local building and safety codes, including requirements for emergency lighting and egress lighting.

It is essential to ensure that the wiring is done correctly and safely when installing LED high bay lights. If you are unsure about any aspect of wiring LED high bay lights, it is recommended to consult with a qualified electrician or lighting technician to ensure that the wiring is done correctly and safely.

The operating temperature of a 400W high bay light will depend on several factors, including the specific model, the ambient temperature of the environment, and the level of ventilation around the fixture. However, as a general rule, high bay lights can get quite hot during operation.

A 400W high bay light typically generates a significant amount of heat due to the amount of power it consumes. The fixture will have a heat sink or other cooling mechanism to dissipate this heat and prevent damage to the fixture or the surrounding area.

In some cases, the surface temperature of the fixture can reach temperatures of 150-200 degrees Fahrenheit (65-93 degrees Celsius) or higher. It is important to handle the fixture with care and avoid touching it during or immediately after use to prevent burns or other injuries.

It is recommended to follow the manufacturer’s instructions for safe operation and maintenance of high bay lights, including proper ventilation and heat dissipation. Regular cleaning and inspection of the fixture can also help to ensure safe and efficient operation.