Factory LED Lighting Manufacturer

We Offers A Wide Variety Of Factory LED Light to meet your every need.

Manufacturer of high-powered Factory LED Lighting systems that providepowerful with low energy consumption,robust, impact resistant,waterproof,high temperature rated,explosion proof rated night illumination for Factories and Manufacturing plants.We offered in different 1800 lm, 6000 lm, 9000 lm and 12000 lm ratings.Most of our lights have a 5-year warranty, and if it fails, you call us. The same salesperson who you worked with will help you get your lights fixed.

Factory LED Lighting

Wandan Lighting specialist offers a wide variety of Factory LED Lighting to meet your every need.

Factory LED lighting refers to the use of LED (light-emitting diode) technology for lighting in factories and other industrial settings. LED lights are a type of solid-state lighting that use semiconductors to convert electrical energy into light, resulting in a highly efficient and long-lasting source of illumination.

In a factory setting, LED lighting can provide numerous benefits over traditional lighting options. LED lights use significantly less energy than traditional lighting sources such as fluorescent or incandescent bulbs, resulting in lower energy costs for the factory. They also have a longer lifespan, reducing maintenance costs associated with replacing bulbs.

LED lights can also provide better lighting quality in a factory environment. They can be designed to provide more uniform and consistent lighting, reducing glare and shadows that can make it difficult for workers to see what they are doing. LED lights also have better color rendering capabilities, making it easier for workers to distinguish between colors and identify potential quality issues with products.

Overall, factory LED lighting can provide a more energy-efficient, cost-effective, and high-quality lighting solution for industrial settings.

Relate Factory LED Lighting

Wandan Lighting specialist offers a wide variety of Factory LED Lighting to meet your every need.

-

Black Fin Industrial LED High Bay Light

-

Wholesale LED Tower Chandelier With Mingwei Power Supply

-

Super Bright Tower Hanging Stadium Lights

-

50Hz Explosion-Proof Emergency Sign Light

-

High Power Ultra-Bright LED High Bay Light For Factory

-

Ultra-Thin LED Industrial And Mining Lamp

-

High Power LED Bulb Light With High Lumen LEDs

-

100w-200w Slim Fin Series LED High Bay Light

-

300W High-Power Bright Fin High Bay Lamp

-

E27 Screw Household 200W Bulb Light

-

E27 & E40 High-Power Aluminum LED Corn Lights For Landscape Used

-

Durable Honeycomb Fin High Bay Lights

-

60w-480w E27/E40 Disk Fin LED Corn Lights

-

100W150W200W240W High quality Die casting aluminum led highbay light

-

Stock 400w led flood light 6500k outdoor lighting spotlight

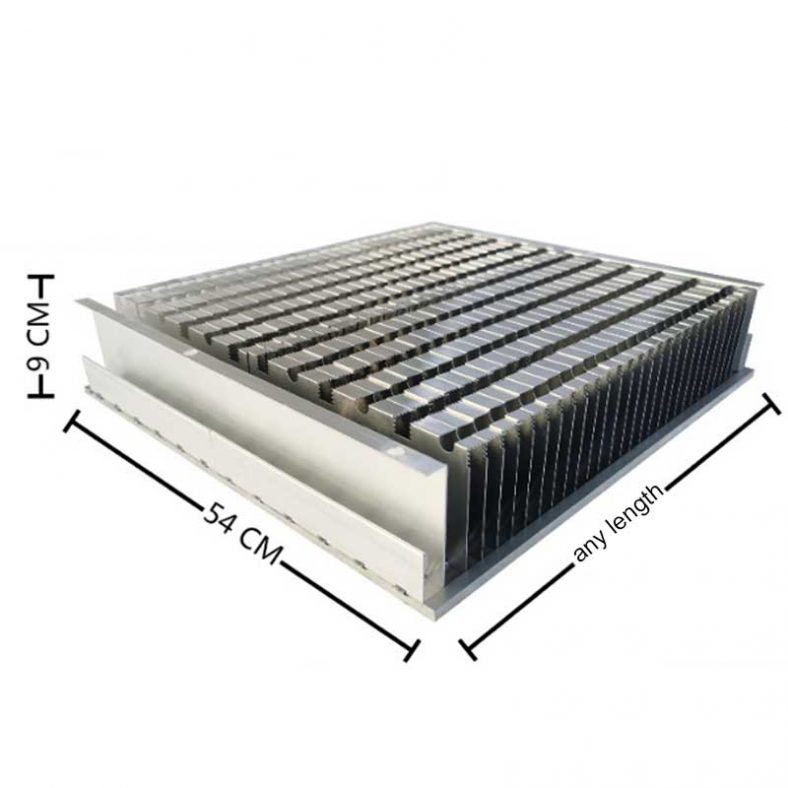

Factory LED Lighting Kits/Parts

Wandan Lighting specialist offers a wide variety of Factory LED Lighting to meet your every need.

Factory LED Light Buy guide

Wandan Lighting specialist offers a wide variety of Factory LED Lighting to meet your every need.

Factory LED lighting has several features that make it a popular choice for industrial settings. Some of the key features of factory LED lighting include:

- Energy efficiency: LED lights are more energy-efficient than traditional lighting options, such as fluorescent and incandescent lights. They use up to 80% less energy and can last up to 25 times longer, which can lead to significant energy and cost savings over time.

- High brightness: LED lights provide high levels of brightness, making them ideal for industrial settings where bright, even lighting is needed.

- Long lifespan: LED lights have a longer lifespan compared to traditional lighting options, which means they need to be replaced less frequently. This can reduce maintenance costs and downtime for the factory.

- Instant on/off: LED lights turn on and off instantly, without any warm-up time. This makes them ideal for settings where lights need to be turned on and off frequently, without delay.

- Improved color rendering: LED lights have a higher Color Rendering Index (CRI) compared to traditional lighting options, which means they can better display the true colors of objects and improve visibility in the workspace.

- Directional lighting: LED lights emit directional lighting, which means they can be used to focus light on specific areas or objects in the workspace.

- Environmental friendliness: LED lights are free of toxic materials, such as mercury, and can be recycled. This makes them a more environmentally-friendly option compared to traditional lighting options.

- Dimming capabilities: Many LED lighting fixtures have dimming capabilities, which allow the light output to be adjusted based on the needs of the space. This can help save energy and increase the lifespan of the LED lights.

Overall, factory LED lighting offers several features that make it a practical and cost-effective lighting solution for industrial settings.

The process for resetting LED lights to their factory settings can vary depending on the specific make and model of the light. Here are some general steps you can follow to reset your LED lights to their factory settings:

- Turn off the power to the LED lights: Make sure the lights are not receiving any power by unplugging them from the power source or turning off the circuit breaker.

- Wait a few seconds: Leave the lights unplugged or with the power turned off for a few seconds to ensure all electrical charges are discharged.

- Press the reset button (if available): Some LED lights have a reset button on the fixture or remote control. Press the reset button and hold it for a few seconds until the light blinks or changes color.

- Use a reset sequence (if applicable): Some LED lights may require a specific sequence of turning them on and off or pressing buttons to reset them. Refer to the user manual or contact the manufacturer for specific instructions on the reset sequence.

- Turn the power back on: Once you have completed the reset process, turn the power back on to the LED lights.

It’s important to note that not all LED lights have a factory reset option. If your LED lights do not have a reset button or a reset sequence, you may need to contact the manufacturer for assistance with resetting the lights to their factory settings.

Yes, it is possible to replace factory HID (High-Intensity Discharge) lighting with LED (Light Emitting Diode) lighting. However, it’s important to note that the process may require some modifications to the existing lighting system and may also require a professional electrician to perform the installation.

Here are some things to consider when replacing factory HID lighting with LED lighting:

- Ballast compatibility: HID lighting systems use ballasts to regulate the amount of current that flows to the lights. LED lighting does not require ballasts, so you will need to remove the existing ballasts if you are switching to LED lights. Alternatively, you can purchase LED lighting kits that are compatible with existing HID ballasts.

- Wiring: LED lights typically require a different wiring setup than HID lights, so you may need to rewire your lighting system to accommodate the new lights.

- Voltage compatibility: LED lights typically have a lower operating voltage than HID lights, so you may need to install a voltage converter to ensure the LED lights receive the correct voltage.

- Light output: When replacing HID lighting with LED lighting, it’s important to consider the desired light output. LED lights typically have a lower lumen output than HID lights, so you may need to install additional LED lights to achieve the desired level of illumination.

- Cost: While LED lighting can offer energy and cost savings over time, the initial cost of replacing HID lighting with LED lighting can be significant. It’s important to weigh the cost of the new LED lighting against the potential energy savings and long-term cost benefits.

Overall, replacing factory HID lighting with LED lighting is possible, but it may require some modifications and professional installation to ensure a safe and effective lighting system.

Yes, it is possible to wire LED lights to a factory harness, but it depends on the specific wiring configuration of the factory harness and the LED lights. Here are some things to consider when wiring LED lights to a factory harness:

- Voltage: It’s important to ensure that the voltage of the LED lights is compatible with the factory harness. LED lights typically operate at lower voltages than traditional lighting, so it’s important to check the voltage requirements of the LED lights and the factory harness before connecting them.

- Wiring configuration: LED lights may have different wiring requirements than traditional lighting, so it’s important to check the wiring configuration of the LED lights and the factory harness to ensure they are compatible.

- Connectors: The connectors on the LED lights and the factory harness may be different, so you may need to purchase adapter connectors or splice the wires together to make a secure connection.

- Current draw: LED lights typically have a lower current draw than traditional lighting, so it’s important to ensure that the factory harness can provide enough current to power the LED lights.

- Fuse protection: It’s important to ensure that the LED lights are properly fused to protect against electrical shorts or overloads.

Overall, wiring LED lights to a factory harness is possible, but it requires careful consideration of the wiring configuration, voltage, current draw, connectors, and fuse protection to ensure a safe and effective lighting system. It may also be helpful to consult the manufacturer or a professional electrician for guidance on the wiring process.

Factory LED lighting can be classified based on several criteria such as the type of LED fixture, the color temperature, the beam angle, and the level of illumination. Here are some common ways to classify factory LED lighting:

- Type of LED fixture: This classification is based on the design and shape of the LED fixture, and includes options such as high bay LED lights, low bay LED lights, linear LED lights, and panel LED lights.

- Color temperature: LED lights come in a range of color temperatures measured in Kelvin (K). The most common color temperatures for factory LED lighting are 4000K, 5000K, and 6000K. 4000K is a neutral white, 5000K is a cool white, and 6000K is a daylight white.

- Beam angle: LED lights are available with different beam angles, which determine how wide or narrow the light is spread. For factory lighting, beam angles typically range from 60 to 120 degrees.

- Level of illumination: The level of illumination required for a factory can vary depending on the size and type of the space. High bay LED lights are typically used in large factories with high ceilings, and require a higher level of illumination than low bay LED lights, which are used in smaller factories with lower ceilings.

- Dimming capabilities: Some factory LED lighting fixtures have dimming capabilities, which allow the light output to be adjusted based on the needs of the space. This can help save energy and increase the lifespan of the LED lights.

- Durability and safety: LED lighting fixtures designed for factories should be durable and safe for use in industrial environments. They should be able to withstand dust, moisture, and vibration, and be rated for safety in hazardous locations.

Overall, the choice of factory LED lighting will depend on the specific needs and requirements of the space, as well as the budget and preferences of the buyer.

The specific process for installing factory LED lights will depend on the make and model of the lights, as well as the type of vehicle or equipment they are being installed on. However, here are some general steps to follow when installing factory LED lights:

- Gather your materials: Make sure you have all the necessary tools and materials for the installation, including the LED lights, mounting brackets, wiring harness, connectors, and any necessary hardware.

- Choose a mounting location: Decide where you want to mount the LED lights. The mounting location should be sturdy and secure enough to support the weight of the lights, and should provide the desired angle and direction of illumination.

- Mount the lights: Attach the mounting brackets to the LED lights, and then attach the brackets to the chosen mounting location using the necessary hardware.

- Wire the lights: Connect the wiring harness to the LED lights using the appropriate connectors. Run the wiring harness to the power source, which may be the vehicle’s battery or a separate power source.

- Install the switch: Install the switch that controls the LED lights in a convenient location, such as on the dashboard or near the steering wheel. Connect the switch to the wiring harness using the appropriate connectors.

- Test the lights: Once the installation is complete, test the LED lights to ensure they are working properly. Turn on the vehicle and activate the switch to turn on the lights. Check the angle and direction of illumination to ensure they are providing the desired level of light.

- Secure and tidy up the wiring: Once you have verified that the LED lights are functioning correctly, secure any loose wiring using cable ties or electrical tape. This will help prevent any loose wires from causing damage to the lights or other components of the vehicle.

It’s important to follow the manufacturer’s instructions for installing factory LED lights, as the specific installation process may vary depending on the make and model of the lights. If you’re unsure about any part of the installation process, it may be helpful to consult the manufacturer or a professional installer for guidance.

The lighting requirements of a factory can vary depending on the type of work being performed, the size of the facility, and other factors. However, here are some general considerations for the lighting requirements of factory LED lights:

- Illumination levels: The amount of illumination required will depend on the type of work being performed. For example, manufacturing processes that require fine detail work may require higher illumination levels than general storage areas.

- Uniformity: It’s important to ensure that illumination levels are uniform throughout the space to prevent glare or dark spots that could cause visual discomfort or safety hazards.

- Color rendering: The color rendering of LED lights should be chosen to provide accurate color representation for the specific type of work being performed. For example, color rendering may be more important for tasks that require color differentiation, such as quality control inspections.

- Energy efficiency: LED lights are highly efficient and can provide significant energy savings compared to traditional lighting. Choosing LED lights with a high lumen per watt ratio can help minimize energy consumption and reduce operating costs.

- Durability: LED lights should be able to withstand the harsh conditions of a factory environment, including exposure to dust, moisture, and temperature fluctuations. Choosing LED lights with a high IP rating can help ensure they are durable enough for the environment.

- Maintenance: LED lights should be easy to maintain and replace when necessary. Choosing LED lights with a long lifespan and easy-to-replace components can help minimize downtime and maintenance costs.

Overall, the lighting requirements of a factory LED light will depend on the specific needs of the facility. It may be helpful to consult with a lighting professional or the LED light manufacturer to determine the best lighting solution for your specific factory.

The safe requirements for factory LED lighting can vary depending on the type of work being performed, the size of the facility, and other factors. Here are some general safety considerations for factory LED lighting:

- Electrical safety: LED lights should be installed and maintained by qualified personnel to ensure they are properly wired and grounded. Electrical components should be properly protected from water, dust, and other environmental hazards.

- Fire safety: LED lights should be installed in accordance with local building codes and fire safety regulations. Electrical components should be properly protected and fire-rated materials should be used for any structural components.

- Eye safety: LED lights can be very bright and can cause eye damage if not used properly. Lighting levels should be carefully selected to prevent glare and excessive brightness, which can cause visual discomfort or safety hazards.

- Ergonomics: Lighting levels and placement should be selected to minimize visual strain and fatigue. Task lighting should be used to provide targeted illumination for specific tasks, and lighting levels should be adjustable to accommodate individual preferences.

- Maintenance: LED lights should be properly maintained to ensure they continue to operate safely and effectively. Maintenance procedures should be established and followed to minimize the risk of accidents or injuries during maintenance activities.

- Environmental safety: LED lights should be disposed of properly to minimize environmental impact. Components containing hazardous materials, such as batteries or electronic components, should be recycled or disposed of according to local regulations.

Overall, the safe requirements for factory LED lighting will depend on the specific needs of the facility. It may be helpful to consult with a lighting professional or the LED light manufacturer to determine the best lighting solution for your specific factory, taking into account all relevant safety considerations.