Food Safe LED Lights Manufacturer

We Offers A Wide Variety Of Food Safe LED Lights to meet your every need.

ISO 9001:2015 certified. NSF certified Manufacturer of standard and custom industrial and Food Safe LED lights.Our Food safe LED lights often have dimming capabilities, allowing you to adjust the lighting levels in different areas of your kitchen based on your needs. Food safe LED lights typically have a color temperature of 3000K to 4000K, creating a warm, inviting environment that highlights food and cooking surfaces. Food safe LED lights are energy efficient, using less energy than traditional lighting options. This can help reduce energy costs and carbon footprint.CAD files accepted.

Food Safe LED Lights

Wandan Lighting specialist offers a wide variety of Food Safe LED Lights to meet your every need.

Food safe LED lights are lighting fixtures designed specifically for use in the food and beverage industry, where strict regulations and standards must be followed to ensure food safety. These LED lights are engineered to meet the specific requirements of this industry, where contamination from lighting fixtures can pose a serious risk to food safety.

Food safe LED lights are made with materials and components that are safe for use in food processing and storage areas. They are typically constructed with corrosion-resistant materials that are easy to clean and disinfect, such as stainless steel or high-grade plastics.Food safe LED lights are designed with shatter-resistant bulbs or protective shields to prevent glass from contaminating food or food-contact surfaces in the event of breakage.

In addition to being made with food-safe materials, food safe LED lights must also meet certain performance standards. For example, they must be able to withstand exposure to harsh cleaning chemicals and extreme temperatures without degradation. They must also be designed to prevent contamination from dust, dirt, and other particles that can accumulate on the surface of the fixture.

Overall, food safe LED lights play a critical role in maintaining food safety in the food and beverage industry. By providing safe and reliable lighting in food processing and storage areas, these fixtures help to prevent contamination and ensure that the products that end up on consumers’ plates are safe and free from harmful bacteria.

Overall, food safe LED lights are designed with the specific needs of commercial kitchens and other food service environments in mind. By providing safe, efficient, and effective lighting solutions, food safe LED lights can help ensure that your food service establishment is clean, sanitary, and operating at its best.

Relate food grade lighting with nsf certified

Wandan Lighting specialist offers a wide variety of Food Safe LED Lights to meet your every need.

Food Safe LED Lights Kits/Parts

Wandan Lighting specialist offers a wide variety of Food Safe LED Lights to meet your every need.

Food Safe LED Lights Buy guide

Wandan Lighting specialist offers a wide variety of Food Safe LED Lights to meet your every need.

NSF certification is a designation awarded by the National Sanitation Foundation (NSF) to products that have been tested and certified to meet specific performance standards related to health and safety. The NSF is an independent organization that sets standards and conducts testing and certification of products related to public health, safety, and the environment.

NSF certification is often required by regulatory agencies and industry organizations in various sectors, including food and beverage, water treatment, healthcare, and consumer products. Products that are NSF certified have undergone rigorous testing and evaluation to ensure they meet established standards for quality, safety, and performance.

In the food and beverage industry, NSF certification is particularly important for products that come into contact with food and drink, such as equipment and utensils. NSF-certified products are designed to meet strict hygiene and safety standards and must be able to withstand the harsh conditions of commercial food processing and storage environments.

Overall, NSF certification is a widely recognized and respected designation that indicates a product has met high standards for safety and performance. For consumers and businesses, choosing NSF-certified products can provide added assurance of quality and safety.

Commercial kitchen lighting requirements are set by various organizations and regulatory agencies to ensure that food preparation and cooking areas are well-lit and safe for employees to work in. Here are some general lighting requirements that commercial kitchens must meet:

- Foot Candles: The amount of light required in a commercial kitchen is measured in foot candles (FC), which is a unit of light intensity. Different areas of the kitchen may require different levels of foot candles, but as a general rule, a minimum of 50 FC is required in food preparation and cooking areas, while 20 FC is required in storage areas.

- Color Rendering Index (CRI): The color rendering index (CRI) is a measure of how well a light source accurately renders colors. In commercial kitchens, it is important that lighting has a CRI of at least 80 to ensure that employees can distinguish between different food colors and textures.

- Uniformity: Lighting must be uniform throughout the kitchen to avoid shadows or hotspots that could make it difficult to see food or work safely. This can be achieved through the use of multiple fixtures that are evenly spaced and angled to provide consistent coverage.

- Durability: Lighting fixtures in commercial kitchens must be durable and able to withstand high temperatures, moisture, and exposure to chemicals and cleaning agents. Fixtures should be made of corrosion-resistant materials and should be designed for easy cleaning and maintenance.

- Energy Efficiency: Commercial kitchens can benefit from energy-efficient lighting solutions that reduce energy consumption and save on utility costs. LED lighting is a popular choice for commercial kitchens due to its low energy usage, long lifespan, and superior performance.

Overall, commercial kitchen lighting requirements are designed to ensure a safe and productive working environment for employees while maintaining high standards of food quality and safety.

The Food and Drug Administration (FDA) Food Code provides guidelines for food safety in retail and food service establishments, including lighting requirements for commercial kitchens. Here are some of the key lighting requirements outlined in the FDA Food Code:

- General Lighting: The FDA Food Code requires that all areas of a food establishment, including storage areas, be provided with adequate lighting to enable employees to see all aspects of their work, including the condition of food, cleaning supplies, and equipment. The minimum light intensity required is 10 foot-candles (FC).

- Task Lighting: In addition to general lighting, the FDA Food Code requires task lighting in specific areas where food is prepared, cooked, or handled. The minimum light intensity required in these areas is 50 FC.

- Color Rendering Index (CRI): The FDA Food Code requires that lighting fixtures have a CRI of at least 70, which ensures that employees can accurately differentiate between food colors and textures.

- Shatter-Resistant Bulbs: All lighting fixtures in a food establishment must use shatter-resistant bulbs or have protective shields to prevent glass from contaminating food or food-contact surfaces in the event of breakage.

- Electrical Safety: All lighting fixtures must be properly installed and maintained to prevent electrical hazards, and any exposed wiring must be covered to prevent contamination.

Overall, the FDA Food Code lighting requirements are designed to ensure that food preparation and cooking areas are well-lit and safe for employees to work in, while also maintaining high standards of food quality and safety. Compliance with these requirements can help food establishments reduce the risk of accidents, improve worker productivity and satisfaction, and maintain a clean and sanitary environment.

Choosing the right food safe LED lights for your commercial kitchen or food service establishment can be a critical decision to ensure that your lighting is safe, efficient, and meets the necessary regulations. Here are some factors to consider when choosing food safe LED lights:

- NSF Certification: Look for LED lights that are NSF certified for use in food service environments. This certification ensures that the lighting fixtures meet the necessary safety and sanitation requirements for use in commercial kitchens.

- Color Rendering Index (CRI): Choose LED lights that have a high CRI to ensure that colors are accurately rendered and food appears fresh and appetizing. A CRI of 80 or higher is recommended.

- Color Temperature: Choose LED lights with a color temperature of 3000K to 4000K to create a warm, inviting environment that highlights food and cooking surfaces.

- Energy Efficiency: Look for LED lights that are energy efficient to help reduce your energy costs and carbon footprint. LED lights are typically more energy efficient than traditional lighting options.

- Dimming Capabilities: Consider LED lights that have dimming capabilities to allow you to adjust the lighting levels in different areas of your kitchen based on your needs.

- Longevity: Look for LED lights with a long lifespan, as this can help reduce the need for frequent maintenance and replacement.

Overall, choosing the right food safe LED lights is an important decision that can impact the safety, efficiency, and overall ambiance of your commercial kitchen or food service establishment. By considering the factors above and working with a reputable lighting supplier, you can select LED lights that meet your specific needs and provide a safe, effective lighting solution for your food service environment.

Food safe LED lights can be classified based on a variety of factors, including the type of food industry application they are used for, the design and materials used in their construction, and the performance standards they meet. Here are a few common classifications of food safe LED lights:

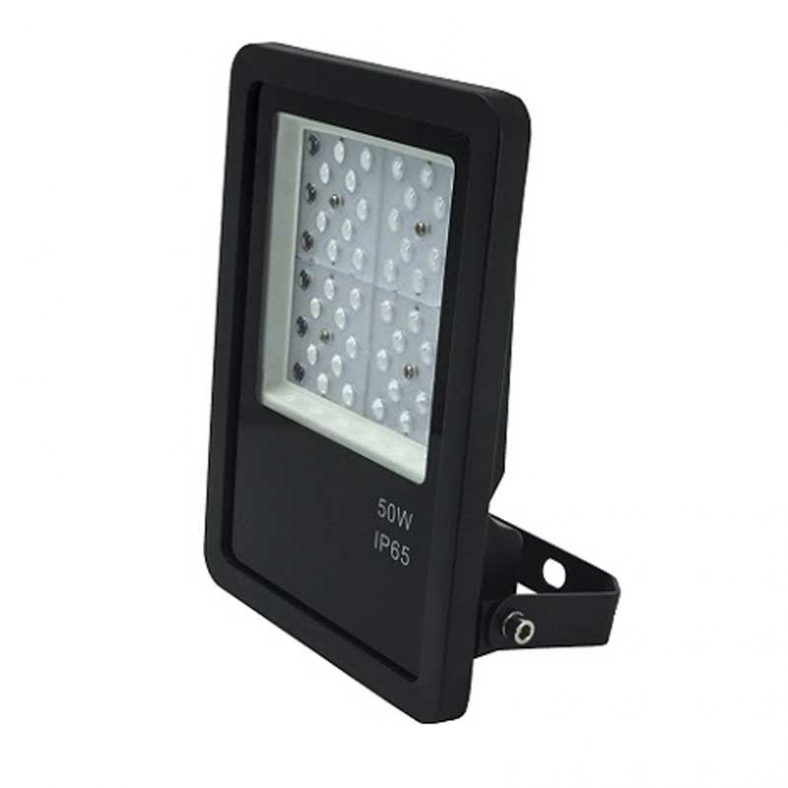

- IP Rating: Food safe LED lights can be classified based on their Ingress Protection (IP) rating, which indicates their ability to resist the ingress of water, dust, and other particles. For example, a fixture with an IP69K rating is designed to withstand high-pressure cleaning and can be used in food processing environments where hygiene is critical.

- Material Construction: Food safe LED lights can also be classified based on the materials used in their construction. For example, fixtures made of stainless steel are often used in the food and beverage industry due to their resistance to corrosion and ease of cleaning.

- NSF Certification: Another way to classify food safe LED lights is based on whether they are certified by the National Sanitation Foundation (NSF). NSF certification indicates that a fixture has been tested and approved for use in food processing and storage areas and meets specific performance standards for food safety.

- Application: Food safe LED lights can also be classified based on the specific application they are designed for. For example, fixtures designed for use in meat processing facilities may have different requirements than fixtures used in bakeries or beverage production facilities.

Overall, the classification of food safe LED lights can vary depending on the specific needs of the food and beverage industry and the regulatory standards that must be met to ensure food safety.

The purpose of implementing food safety facility certification is to ensure the safety of food in the production, processing, manufacturing, 5261 preparation, and consumption processes. It is a scientific, reasonable, and systematic method for hazard identification, evaluation, and control. Identify possible links in the food production process and take appropriate control measures to prevent the occurrence of hazardous 4102 hazards. By monitoring and controlling every 1653 steps of the processing process, the probability of internal hazards occurring is reduced.

The 2113 facilities for food safety equipment include: disinfection cabinets, cleaning cabinets, freezers, freezers, ultraviolet disinfection lamps, fly proof lamps, secondary dressing rooms, oil traps, wash basins, trash cans, washing basins, air conditioners, etc.

Handwashing stations are an important part of maintaining food safety and preventing the spread of disease in commercial kitchens and food service establishments. Here are the minimum lighting requirements for handwashing stations:

- Illumination Level: Handwashing stations must have adequate lighting to ensure that employees can properly wash their hands and see any debris or contamination on their hands. The minimum light intensity required is 20 foot-candles (FC) at the handwashing sink.

- Task Lighting: In addition to general lighting, task lighting may be required to ensure that employees can see their hands and any debris or contamination during the handwashing process.

- Color Rendering Index (CRI): The lighting fixtures used in handwashing stations should have a CRI of at least 80 to ensure that employees can accurately differentiate between different colors and textures on their hands.

Overall, the lighting requirements for handwashing stations are relatively minimal compared to other areas of the commercial kitchen. However, it is important to ensure that the lighting is adequate to prevent the spread of disease and maintain food safety standards. By providing proper lighting at handwashing stations, food establishments can help ensure the health and safety of their employees and customers.

Food preparation areas in commercial kitchens require adequate lighting to ensure that food is prepared safely and efficiently. Here are the minimum lighting requirements for food preparation areas:

- Illumination Level: The minimum illumination level for food preparation areas is 50 foot-candles (FC). This level of lighting is required to ensure that employees can see food and food-contact surfaces clearly and identify any contamination or foreign objects.

- Task Lighting: In addition to general lighting, task lighting may be necessary to ensure that employees can see their work areas clearly and prevent accidents. Task lighting should provide at least 100 FC of illumination.

- Color Rendering Index (CRI): The lighting fixtures used in food preparation areas should have a CRI of at least 70 to ensure that employees can accurately differentiate between different colors and textures of food.

- Shatter-Resistant Bulbs: All lighting fixtures in food preparation areas must use shatter-resistant bulbs or have protective shields to prevent glass from contaminating food or food-contact surfaces in the event of breakage.

- Electrical Safety: All lighting fixtures must be properly installed and maintained to prevent electrical hazards, and any exposed wiring must be covered to prevent contamination.

Overall, the lighting requirements for food preparation areas are designed to ensure that food is prepared safely and efficiently, with a minimum risk of contamination or accidents. By providing adequate lighting in these areas, food establishments can improve the quality of their food, reduce the risk of accidents, and maintain a clean and sanitary environment.